Our quality system

QHSE Politic

FORGINAL industrie’s quality, safety and environment strategy is set out in a 5-year improvement plan, called DEFI. Each year, the quality policy sets out the practical strategies based on this plan, which have to cover the areas of quality, safety and environment. The management carries out a review twice a year to monitor the progress of the quality policy and the improvement plan.

Quality

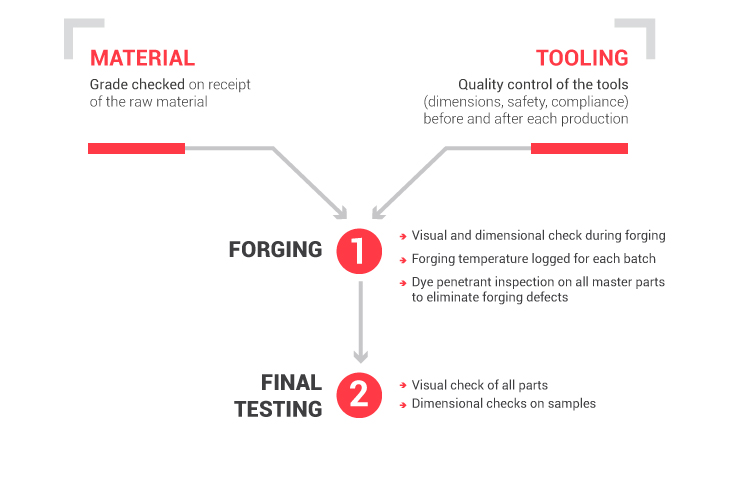

PROCESS / TRACEABILITY / TESTS

Quality is ensured during the manufacturing process by means of a tracking sheet identifying each batch and by the use of appropriate batch packaging to which a permanent tracking label is attached.

The tracking sheet accompanies the batch of parts from tooling right through to final testing. It identifies and gives details of all the steps in the manufacturing process, the traceability information for the batch and the necessary tracking documents.

Each test carried out during production is recorded and the sheet kept for at least 10 years, together with the records for the batch to which it refers.

The tests and checks listed above are carried out on each batch produced at FORGINAL industrie. We can of course offer additional specific checks according to each of your projects. Please feel free to contact us.

Internal audits

The quality department carries out a full audit of FORGINAL industrie’s quality system every year, which leads to corrective actions, each of which is reviewed and signed off during the year. Environmental and product audits are carried at the same time, to ensure that the company’s processes are fully effective, mainly with regard to the following points :

- Qualification of staff

- Qualification of production tools

- Continuous improvement system: all the teams at FORGINAL industrie are committed to submitting non-conformity reports and suggestions for improvements. Each risk or non-conformity is examined and dealt with in working groups. All this information is logged, to ensure that the technical knowledge of our tools and the parts made is maintained over time.

- SPC (statistical process control)

External audits

FORGINAL industrie has the following certifications :

- ISO 9001:2015 for drop forging steel and alloy parts in small and medium series

- AD 2000 Directive 2014/68/EU for parts used in pressure equipment

External audits are carried out annually. They are used as sources for improvement within the company. Robustness tests are carried out on our quality system (documentation system, customer and normative requirements, traceability, quality assurance plan, records, staff accreditation, etc.) to ensure continuous improvement.

Customer audit

FORGINAL industrie works completely transparently in partnership with its customers. We are always happy to welcome you for visits or audits whenever you want. Numerous customers come and audit us every year. Please feel free to contact us, we are happy to answer any questions.

Supplier audits

FORGINAL industrie has a list of subcontractors who are approved according to precise, rigorous quality criteria. Depending on the criticality of the supplier, documentation or on-site audits are regularly organised. An assessment is carried out twice a year to maintain their qualification. If there is any deterioration, quality or logistics action plans are called for, together with increased monitoring by us. Suppliers may be removed from the list if the quality level is considered to be unsatisfactory.

Security

The company’s labour policy

FORGINAL industrie invests every year to improve working conditions within the company.

The risks of developing musculoskeletal disorders, and also the psychological and social risks to which its teams are exposed, are examined. The management is committed to reducing these risks, by actively listening and introducing appropriate measures.

FORGINAL industrie’s management has also made staff training a priority in order to increase the loyalty of its teams and enhance their skills.

All newcomers are given an initial introduction to the company and have period of mentoring. They learn about their duties and any risks associated with their jobs, accompanied by an experienced mentor.

The safety policy is based on feedback from workplace first-aiders within the company and from the company’s committee for health and safety at work.

Environment

Procedures for ISO 14001 certification

FORGINAL industrie plans to start the procedures for ISO 14001 certification in the medium term.

Environmental protection measures have already been put in place. These include:

- Sorting and recycling of waste (metal, wood, etc.)

- Introduction of an active carbon water treatment system for dye penetrant inspection products

- Continuous monitoring of waste water, with recording of the results and more in-depth annual tests

- Environmentally responsible choice of packaging: cardboard boxes and wooden pallets

- FORGINAL industrie has installed a settling tank for treating rainwater

Products purchased and used at FORGINAL industrie comply with the REACH requirements. We require our suppliers to comply fully with these requirements, and we check them periodically on this.