Forginal Industrie

Subcontractor for custom-forged parts in small and medium series up to 10 kg

Made in France

Our workshops are located in the Thiers industrial area.

Innovation

With experts dedicated to research and development.

Know-how

Over 50 years’ experience in metal parts manufacturing

Our production process for tailor-made solutions

Would you like to find out more?

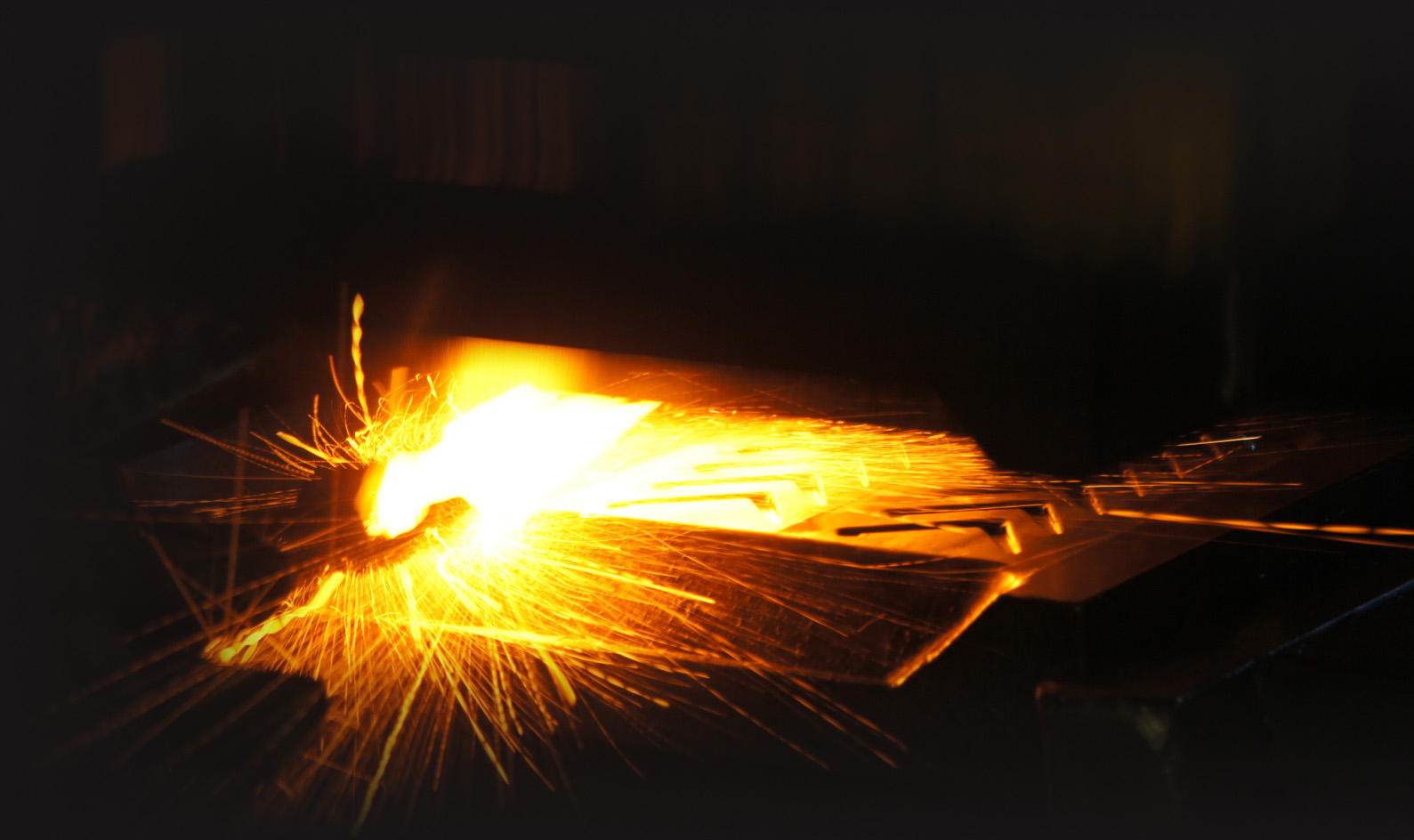

Discover our manufacturing processes, where expertise and innovation meet to create precision parts. We combine advanced forging techniques with rigorous quality control to ensure the performance and reliability of every component.

Sourcing materials

Toolmaking

Hot forging

Cold cutting

Heat treatment

Precision machining

Surface treatments

Assembly of subassemblies

Quality control

Certified expertise

Your forging partner for small and medium production runs in 12 key sectors.

With its extensive expertise, FORGINAL Industrie operates in more than 12 different sectors, providing innovative, customized solutions to meet your specific needs.

Aeronautics

Forging in aeronautics: a guarantee of safety and reliability

Safety part

Specialist in forging safety-critical parts, where reliability and strength are essential

Lifting and handling

Forged parts for handling equipment: robustness and performance

Tools

Tool manufacturing: French craftsmanship

Industrial Valves

French expertise in forged industrial valves

Offshore wind, hydrogen

Our expertise serving strategic sectors

Agricultural / Viticultural

Manufacturer of agricultural wear parts: recognized expertise

Rail transport

Your forging partner for the railway sector

Defense / Armaments

Forged components for the defense industry

Forged fittings

FORGINAL Industrie, European leader in stainless steel forged fittings

Food industrie

Industrial forging: a key process for the agri-food industry

Leisure

Manufacturing forged parts for leisure activities

Discover our manufacturing processes

Discover our manufacturing processes, where expertise and innovation meet to create precision parts. We combine advanced forging techniques with rigorous quality control to ensure the performance and reliability of every component.

Innovation for the forge

Forginal is an agile and responsive start-up, revolutionizing the forging industry with cutting-edge technologies. Here are our main assets:

Fast adaptability

to technological developments and market needs.

Advanced simulation software

to optimize product quality and efficiency.

Total traceability

guaranteeing contamination-free, standards-compliant products.